Executive Summary

Discover the efficiency of planning your project around a Wafflemat foundation from the start—site development remains just as straightforward as with any traditional foundation. What sets it apart? The Wafflemat system elevates higher above the graded pad than ribbed or uniform-thickness slabs, allowing street and curb heights to rise an additional 6 to 8 inches. This smart design delivers substantial reductions in excavation costs and spoils off-haul, while minimizing dirt work to accelerate site development cycles and unlock even more savings.

Beyond new builds, seamlessly adapt existing house plans to incorporate Wafflemat—it's a breeze. As a precision-engineered foundation, it empowers architects, engineers, concrete specialists, and post-tension (P/T) experts familiar with the system to swiftly replace ribbed or uniform-thickness slab-on-ground options with the superior strength and durability of Wafflemat. The result? A smarter choice that pays off through proven cost efficiencies.

Grading and Wafflemat

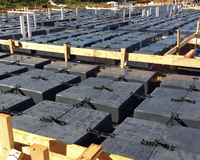

The innovative Wafflemat foundation forming system is designed to sit directly on pad grade, featuring robust 8.5-inch or 12-inch high, 19 x 19-inch thermal-grade, heat-resistant Waffleboxes. By interconnecting these Waffleboxes and spacing them evenly across the building footprint, you create a resilient base. A post-tensioned reinforced slab—typically 4 to 6 inches thick—is then poured over it, with the Waffleboxes engineered to accommodate soil movement while forming strong concrete beams throughout the interior and perimeter for unmatched stability.

For builders transitioning mid project, it is important to review the grading plans and verify that Wafflemat is strategically planned. It is essential to account for the system's elevated floor height and its positive impacts on site plans, including optimized slope, drainage, and floor elevation relative to curbs and streets.

In comparison, a standard uniform-thickness slab tops out at 8 to 16 inches above the graded pad, while ribbed slabs sit slightly lower (4 to 6 inches) due to pre-pour trenching. Wafflemat, however, achieves a typical floor height of 12.5 inches above pad grade (8.5-inch Wafflebox + 4-inch slab), as its ribs rest atop the pad without invasive cuts. For most one- or two-story homes, this modest increase stays well below maximum building height limits, posing no issues.

Should the elevated height reveal more foundation than desired for aesthetics, a simple solution awaits: add a few extra inches of backfill around the perimeter during finish grading. In fact, this approach often enhances your project by 1) cutting down on spoils that need off-hauling, and 2) boosting natural runoff drainage away from the foundation for long-term protection.